| Size: | |

|---|---|

| Availability: | |

| Quantity: | |

| Material | Extruder | Width | Strap quantity | Output kg/h | |

| PP | Ø75 | 5-19 | 2 | 120-150 | |

| PP | Ø90 | 5-19 | 4 | 200-250 | |

| PP | Ø120 | 5-19 | 4-8 | 300-350 | |

| PET/PP | Ø90 | 9-19 | 2 | PP | 120-150 |

| PET/PP | Ø90 | 9-19 | 2 | PET | 200-250 |

| PET | Ø110 | 9-25 | 4 | 350-400 | |

| PET | Ø120 | 9-32 | 4 | 500-600 | |

| PET | Ø150 | 9-329-32P999T | 4-8 | 800-900 | |

| Strap width | 9-25mm |

| Production speed | ≤160m/min X 4(2) |

| Stretching ratio | 4-6 |

| Max.output | 200kg/h Max |

Characteristic:

Choice of single or twin screw extruder.

Production can use 100% recycled material to obtain a high add value commodity like strapping band.

PLC manages automatically the extruder's working parameters in according with the running condition; Material treatment, extrusion, stretching, annealing and taking up units are all synced with the PLC.

All components are controlled and monitored through PLC.

PET or PP straps can be produced with the same technology, to change line set-up from one to the other only take in few minutes.

High-advanced ABA co-extrusion technology, not only improve strap's tensile strength but also help the peel strength after welding.

Double column 4 positioned filter chambers, 100% full automatic self-cleaning screen changer, working non-stop during screen changing, it ensures the straps quality is not affected throughout the production.

Choice of ordering one, two, four, six and eight straps production line.

Choice of either servo or torque motor for winding machine.

PET strapping band production line consists:

1. SHR-1500 Crystallizing and Drying and I. V increasing unit

2. Twin screw extruder

3. Screen changer

4. Gear pump

5. Mould

6. Water cooling tank

7. Pre-heating unit No. 1

8. Stretching oven

9. Stretching unit No. 1

10. Stretching unit No. 2

11. Embossing unit

12. Fixing unit

13.3-roller hauling off

14. Winder

Finished product features:

PET strap is an alternative to steel strapping, polypropylene strapping material such as new environmentally friendly

packaging materials, mainly used for all kinds of Strapping, such as pallets, cartons, boxes, plastic boxes and other

types of bundled packaging. It also can be used for direct binding, for example: cotton, steel, timber and other packaging.

Now it widely used in cotton, steel, paper, chemical fiber, electronics, food, timber, building materials, packaging and other industries area.

Main features are as follows:

(1)Safety and environmental protection:safe for use, not easy to hurt, according with EU environmental directives, for example ROSH.

(2)Low cost:It is the most cost-effective in new environmentally friendly packaging materials products.

(3)Easy to use:Suitable for fully automatic balers, manual balers and other packaging machinery quickly and convenient to use.

(4)Excellent toughness: Between -50 ~ 100 ºC temperature, it is fully capable of normal use, and maintains

excellent flexibility.

(5)Look beautiful: Finish bundled items look beautiful, does not pollute the items, never rust.

(6)Very good strength: Can provide up to 470 MPA tensile strength to protect the safety of Strapping.

Exhibitons

Production line introduction:

PET strapping extrusion line : PET strap, also known as plastic steel band, which is used in place of steel on the world of a

new environmentally friendly packaging materials, the development of new materials in recent years the cost of success and

a substantial decline, have been widely used in the steel industry, chemical fiber industry, aluminum ingots, paper, brick kiln

industry, screw industry, tobacco industry, electronics, textiles and wood, etc.; is replaced by a new high-strength steel strapping,

is the world's most widely used for steel products.

For users to save the cost of equipment purchases, especially on the initial investment of users, a large new R & D design light

(economic type) PET packing belt production equipment, can achieve single one, a two belt production, production of up to 150kg/h.

The raw material processing and extrusion system:

High efficiency pre crystallization and drying system, the equipment can be used 100% bottles of recycled

materials, the production of high value-added packaging belt. Special design of PET special screw, single and

double screw extruder can be used to choose:

Double column exhaust type net changing device:

Embossing machine:

The hydraulic control can be set according to user requirements, embossing design, embossed with the

synchronization control system, precise adjustment on the position of embossing roll and embossing

strength.

heat setting:

Special setting technology, to ensure that the rapid setting of belt products, to eliminate the back of the PET

belt to remove the internal stress, to ensure that the belt size accuracy and quality.

Servo winding machine and torque motor winding machine can choose:

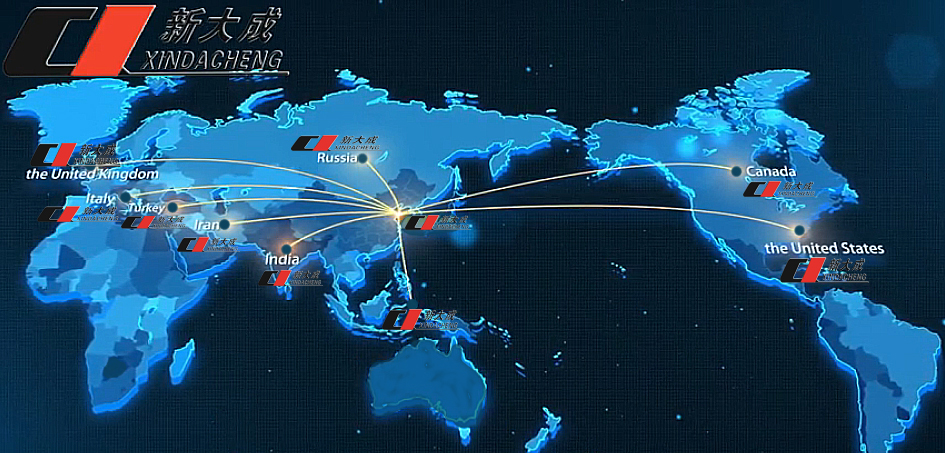

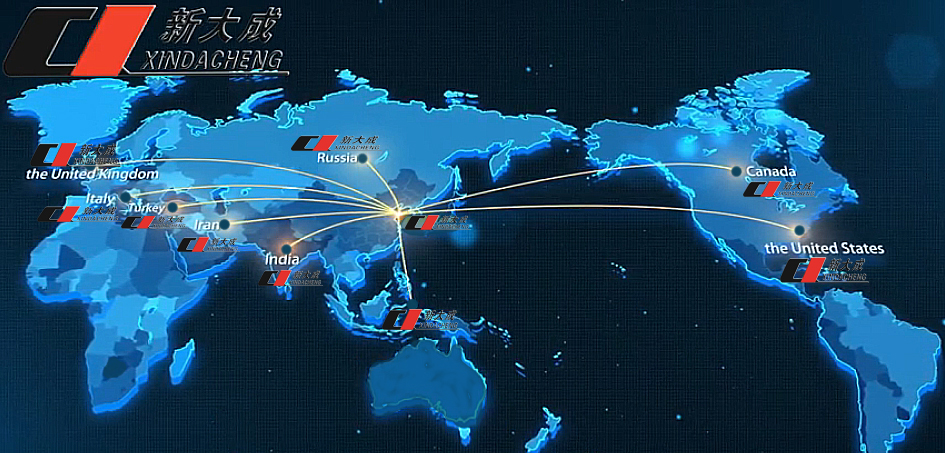

Qingdao Xindacheng Plastic Machinery Co., Ltd The company mainly engages in research, development,

design, manufacture and sales service of new type plastic machinery, is able to provide "Turn-key project" of complete set

of production line for many plastic product. It owns powerful technology strength, gathers professional scientific and

research talents in top grade macromolecule material national wide, polymer processing, industrial automatization and

marketing.

Oriented by human, Xindacheng considers that the innovation and credit is the most important. It will offer first-class

product and considerate service to help you in accomplishing great business and cooperate with together to create

new era in plastic machinery industry.Xindacheng always considers that customers' interest is the first important. Over

decades, Xindacheng's product spreads all over the country and exported to more than 40 countries and regions such as,

U.S. Italy, Canada, South Korea, Japan, Russia, Ukraine, Czech, Turkey, Mexico, Iran, Saudi Arabia, Egypt, Indonesia,

Singapore, Taiwan, HK, Malaysia, and wins customers' reputations.Company board chairman and staff warmly welcome

friends from all circles to visit us.

| Material | Extruder | Width | Strap quantity | Output kg/h | |

| PP | Ø75 | 5-19 | 2 | 120-150 | |

| PP | Ø90 | 5-19 | 4 | 200-250 | |

| PP | Ø120 | 5-19 | 4-8 | 300-350 | |

| PET/PP | Ø90 | 9-19 | 2 | PP | 120-150 |

| PET/PP | Ø90 | 9-19 | 2 | PET | 200-250 |

| PET | Ø110 | 9-25 | 4 | 350-400 | |

| PET | Ø120 | 9-32 | 4 | 500-600 | |

| PET | Ø150 | 9-329-32P999T | 4-8 | 800-900 | |

| Strap width | 9-25mm |

| Production speed | ≤160m/min X 4(2) |

| Stretching ratio | 4-6 |

| Max.output | 200kg/h Max |

Characteristic:

Choice of single or twin screw extruder.

Production can use 100% recycled material to obtain a high add value commodity like strapping band.

PLC manages automatically the extruder's working parameters in according with the running condition; Material treatment, extrusion, stretching, annealing and taking up units are all synced with the PLC.

All components are controlled and monitored through PLC.

PET or PP straps can be produced with the same technology, to change line set-up from one to the other only take in few minutes.

High-advanced ABA co-extrusion technology, not only improve strap's tensile strength but also help the peel strength after welding.

Double column 4 positioned filter chambers, 100% full automatic self-cleaning screen changer, working non-stop during screen changing, it ensures the straps quality is not affected throughout the production.

Choice of ordering one, two, four, six and eight straps production line.

Choice of either servo or torque motor for winding machine.

PET strapping band production line consists:

1. SHR-1500 Crystallizing and Drying and I. V increasing unit

2. Twin screw extruder

3. Screen changer

4. Gear pump

5. Mould

6. Water cooling tank

7. Pre-heating unit No. 1

8. Stretching oven

9. Stretching unit No. 1

10. Stretching unit No. 2

11. Embossing unit

12. Fixing unit

13.3-roller hauling off

14. Winder

Finished product features:

PET strap is an alternative to steel strapping, polypropylene strapping material such as new environmentally friendly

packaging materials, mainly used for all kinds of Strapping, such as pallets, cartons, boxes, plastic boxes and other

types of bundled packaging. It also can be used for direct binding, for example: cotton, steel, timber and other packaging.

Now it widely used in cotton, steel, paper, chemical fiber, electronics, food, timber, building materials, packaging and other industries area.

Main features are as follows:

(1)Safety and environmental protection:safe for use, not easy to hurt, according with EU environmental directives, for example ROSH.

(2)Low cost:It is the most cost-effective in new environmentally friendly packaging materials products.

(3)Easy to use:Suitable for fully automatic balers, manual balers and other packaging machinery quickly and convenient to use.

(4)Excellent toughness: Between -50 ~ 100 ºC temperature, it is fully capable of normal use, and maintains

excellent flexibility.

(5)Look beautiful: Finish bundled items look beautiful, does not pollute the items, never rust.

(6)Very good strength: Can provide up to 470 MPA tensile strength to protect the safety of Strapping.

Exhibitons

Production line introduction:

PET strapping extrusion line : PET strap, also known as plastic steel band, which is used in place of steel on the world of a

new environmentally friendly packaging materials, the development of new materials in recent years the cost of success and

a substantial decline, have been widely used in the steel industry, chemical fiber industry, aluminum ingots, paper, brick kiln

industry, screw industry, tobacco industry, electronics, textiles and wood, etc.; is replaced by a new high-strength steel strapping,

is the world's most widely used for steel products.

For users to save the cost of equipment purchases, especially on the initial investment of users, a large new R & D design light

(economic type) PET packing belt production equipment, can achieve single one, a two belt production, production of up to 150kg/h.

The raw material processing and extrusion system:

High efficiency pre crystallization and drying system, the equipment can be used 100% bottles of recycled

materials, the production of high value-added packaging belt. Special design of PET special screw, single and

double screw extruder can be used to choose:

Double column exhaust type net changing device:

Embossing machine:

The hydraulic control can be set according to user requirements, embossing design, embossed with the

synchronization control system, precise adjustment on the position of embossing roll and embossing

strength.

heat setting:

Special setting technology, to ensure that the rapid setting of belt products, to eliminate the back of the PET

belt to remove the internal stress, to ensure that the belt size accuracy and quality.

Servo winding machine and torque motor winding machine can choose:

Qingdao Xindacheng Plastic Machinery Co., Ltd The company mainly engages in research, development,

design, manufacture and sales service of new type plastic machinery, is able to provide "Turn-key project" of complete set

of production line for many plastic product. It owns powerful technology strength, gathers professional scientific and

research talents in top grade macromolecule material national wide, polymer processing, industrial automatization and

marketing.

Oriented by human, Xindacheng considers that the innovation and credit is the most important. It will offer first-class

product and considerate service to help you in accomplishing great business and cooperate with together to create

new era in plastic machinery industry.Xindacheng always considers that customers' interest is the first important. Over

decades, Xindacheng's product spreads all over the country and exported to more than 40 countries and regions such as,

U.S. Italy, Canada, South Korea, Japan, Russia, Ukraine, Czech, Turkey, Mexico, Iran, Saudi Arabia, Egypt, Indonesia,

Singapore, Taiwan, HK, Malaysia, and wins customers' reputations.Company board chairman and staff warmly welcome

friends from all circles to visit us.